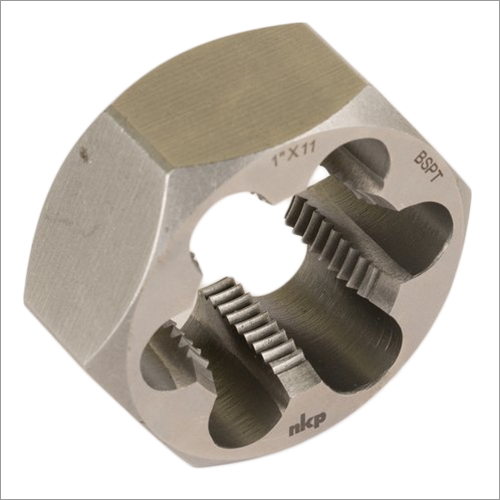

Rethreading Hex Die Nut

Price 100-5000 INR/ Piece

MOQ : 1 Piece

Rethreading Hex Die Nut Specification

- Mould Base

- High-Quality Alloy Steel

- Core Material

- High-Speed Steel (HSS)

- Working Process

- Thread Repair, Recutting Worn or Damaged Threads

- Life Span

- Long Service Life (Depends on Usage & Material)

- Tolerance

- High Precision, Tight Tolerance

- Material

- Alloy Tool Steel, Hardened & Tempered

- Shaping Mode

- Forged / Machined

- Punch Dies

- Compatible with Standard Die Stocks

- Die Head

- Hexagonal Die Head, Standard

- Surface Finish

- Black Oxide, Corrosion Resistant

- Hex Size

- Varies (Conforms to DIN Standard)

- Thread Type

- Metric, UNC, UNF, BSW, BSF (As per Requirement)

- Cutting Direction

- Right Hand (Standard); Left Hand on Request

- Thread Size Range

- M3 to M30 (Available in Metric & Inch)

- Weight

- Depends on Die Size (Approx. 50g - 500g)

- Application

- Thread Rethreading, Thread Cleaning, Maintenance & Repair

- Colour

- Black / Silver Finish

Rethreading Hex Die Nut Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1-2 Days

About Rethreading Hex Die Nut

The offered Rethreading Hex Die Nut is a highly durable and rigid mechanical components which is used for the marking of highly finished fastening threads with high uniformity. Top grade steel which is alloyed with various types of engineering materials which results in higher tensile and compressive strength that makes it suitable for industrial applications. Rethreading Hex Die Nut availed by us are free from manufacturing flaws. Customers can get this tool from our company in large quantities as per your demands.

Product details

| I deal in | New Only |

| Location | PAN India |

| Country of Origin | Made in India |

| Material | SS |

| Size | All |

| Brand | nkp |

Precision Engineered for Versatility

This hex die nut accommodates a wide thread size range from M3 to M30 and multiple thread types, making it perfect for a variety of industrial and maintenance tasks. Its hexagonal shape allows easy use with standard die stocks, and both right-hand and left-hand cutting directions are available to suit different applications.

Durable Construction for Longevity

Manufactured using premium alloy steel and a high-speed steel core, the die nut offers exceptional hardness and resilience. The black oxide or silver finish provides corrosion resistance, supporting a long service life even under demanding repair or rethreading conditions.

Ideal for Maintenance and Repair

Designed for recutting and cleaning worn or damaged threads, this tool ensures that machinery and fasteners remain in optimal condition. Its precise manufacturing and strict conformity to standards make it a reliable choice for industries prioritizing high-quality thread maintenance.

FAQ's of Rethreading Hex Die Nut:

Q: How do I use a rethreading hex die nut for thread repair?

A: To repair damaged or worn threads, select the appropriate die nut based on the thread type and size. Secure the die in a compatible standard die stock, align it with the bolt or rod, and rotate in the correct direction (right or left hand as required). Apply steady pressure and lubricate as necessary to recut or clean the threads efficiently.Q: What thread sizes and types are supported by this die nut?

A: This hex die nut supports thread sizes ranging from M3 to M30 and is available for Metric, UNC, UNF, BSW, and BSF thread types as required. Both metric and inch specifications are available, providing broad compatibility for maintenance and repair tasks.Q: When should I use a rethreading die nut?

A: Use this tool whenever threads on fasteners, bolts, or rods become damaged, corroded, or clogged. It is ideal for regular maintenance, repair operations, or when precise thread restoration is needed to extend the life of essential components.Q: Where can this die nut be used?

A: Suitable for use in industrial workshops, automotive service centers, machinery maintenance, and construction sites-anywhere thread restoration, cleaning, or repair is required. Its broad size and thread compatibility make it a valuable tool in many sectors.Q: What are the benefits of using a black oxide, corrosion-resistant finish?

A: The black oxide or silver finish protects against rust and corrosion, increasing the tool's durability and ensuring reliable performance even in challenging environments. This helps maintain the integrity of the threads and extends the tool's lifespan.Q: What advantages does the high-speed steel (HSS) core offer?

A: A high-speed steel core imparts superior cutting performance and wear resistance, allowing for efficient and precise thread recutting and cleaning, as well as a long service life even during high-frequency industrial usage.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS