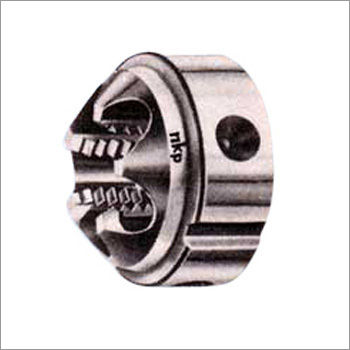

Circular Thread Cutting Dies

Price 100-5000 INR/ Piece

Circular Thread Cutting Dies Specification

- Coating Type

- Oxide or Uncoated

- Material

- High Speed Steel (HSS) / Alloy Steel

- Features

- High durability, Reusable, Corrosion resistant

- Hardness

- 5862 HRC

- Cutting Capacity

- Varies by size

- Length

- Standard as per die type

- Machine Type

- Lathe, Bench, Hand Pipe Threader

- Cutting Accuracy

- Precision-cut threads

- Shape

- Circular

- Operation Type

- Manual, Semi-automatic

- Tool Type

- Hand Tool, Machine Tool

- Operate Method

- Manual or with die stock handle

- Coating

- Optional

- Cutter Type

- Thread Cutting Die

- Cutting Force

- High

- Cutting Speed

- Suitable for manual and machine use

- Diameter

- Range 10 mm - 65 mm

- Maximum Torque

- Depends on material and thread size

- Processing Type

- Thread Cutting

Circular Thread Cutting Dies Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1-2 Days

About Circular Thread Cutting Dies

Circular Thread Cutting Dies is highly durable and robust industrial components which is commonly used in the manufacturing of various types of threaded components. It is designed by our skilled professionals by using latest machining technologies which gives high class finish and excellent dimensional accuracy. It is provided with a steam oxide coating which is applied to resist welding. Circular Thread Cutting Dies can be easily fixed to the power tools with the help of special fixing attachments.

Product details

| Country of Origin | Made in India |

| Usage/Application | Industrial |

| Surface Finishing | Polished |

| Shape | All |

| Material | SS |

| Color | Silver |

| Brand | nkp |

Versatile Threading Options

Our circular thread cutting dies accommodate various thread formats, including Metric, BSP, UNF, and UNC. This flexibility ensures compatibility with diverse industrial, plumbing, and mechanical applications, streamlining your thread-cutting processes and eliminating the need for multiple tools.

Engineered for Precision and Durability

Crafted from premium High Speed Steel or Alloy Steel, these dies deliver consistent, precision-cut threads. Their robust construction ensures high durability, corrosion resistance, and the ability to withstand high cutting forces, making them dependable for repeated use on different materials.

Adaptable for Multiple Operations

Circular thread cutting dies are compatible with manual and semi-automatic machines like lathes, bench tools, and hand pipe threaders. Whether you operate them by hand or with machine assistance, the dies maintain excellent cutting integrity, allowing seamless, accurate threading under varied conditions.

FAQ's of Circular Thread Cutting Dies:

Q: How are circular thread cutting dies used for external threading?

A: Circular thread cutting dies are employed to cut precise external threads onto rods, bolts, and pipes by rotating the die onto the workpiece, either manually using a die stock handle or with a compatible machine tool. Cutting oil is recommended to enhance performance and extend tool life.Q: What thread types and sizes can these dies accommodate?

A: These dies support Metric, BSP, UNF, and UNC thread standards, with pitch ranges from 0.5 mm to 2.5 mm or 8 TPI to 32 TPI, covering a vast array of industrial requirements in various diameters from 10 mm to 65 mm.Q: When should I regrind or replace a thread cutting die?

A: Regrind the cutting edges when you notice decreased cutting performance or diminished thread accuracy. Thanks to their high-grade material, these dies can be reground multiple times before replacement is necessary.Q: Where are these dies commonly used in industry?

A: They are widely utilized in manufacturing, plumbing, automotive, and maintenance industries across India, wherever precise external threading of rods, bolts, or pipes is required using hand or machine tools.Q: What is the recommended cutting process for maximum efficiency?

A: For best results, ensure the workpiece is securely clamped, use appropriate cutting oil, and apply steady, consistent force during threading. Operate within the recommended temperature range (up to 250C) to maintain die lifespan and thread quality.Q: Can these dies be used both manually and with machines?

A: Yes, these thread cutting dies are suitable for manual operation with a die stock handle, as well as for semi-automatic or machine-based tools like lathes and bench threaders, offering flexibility for various work environments.Q: What are the key benefits of using circular thread cutting dies?

A: Key benefits include precision-cut threads, high durability, corrosion resistance, reusable and regrindable properties, and adaptability for a range of applications. Their robust construction ensures efficient threading and long service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Circular Thread Cutting Category

Acorn Circular Threading Dies

Price 100-5000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Coating : Optional Black Oxide

Operate Method : Manual or Mechanical

Tool Type : Threading Tool

Cutting Speed : Standard suitable for manual and machine use

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS