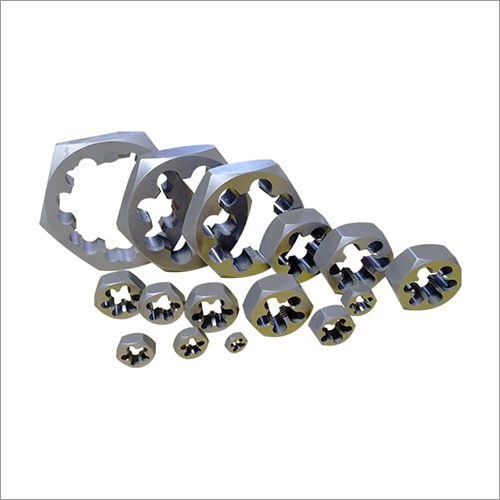

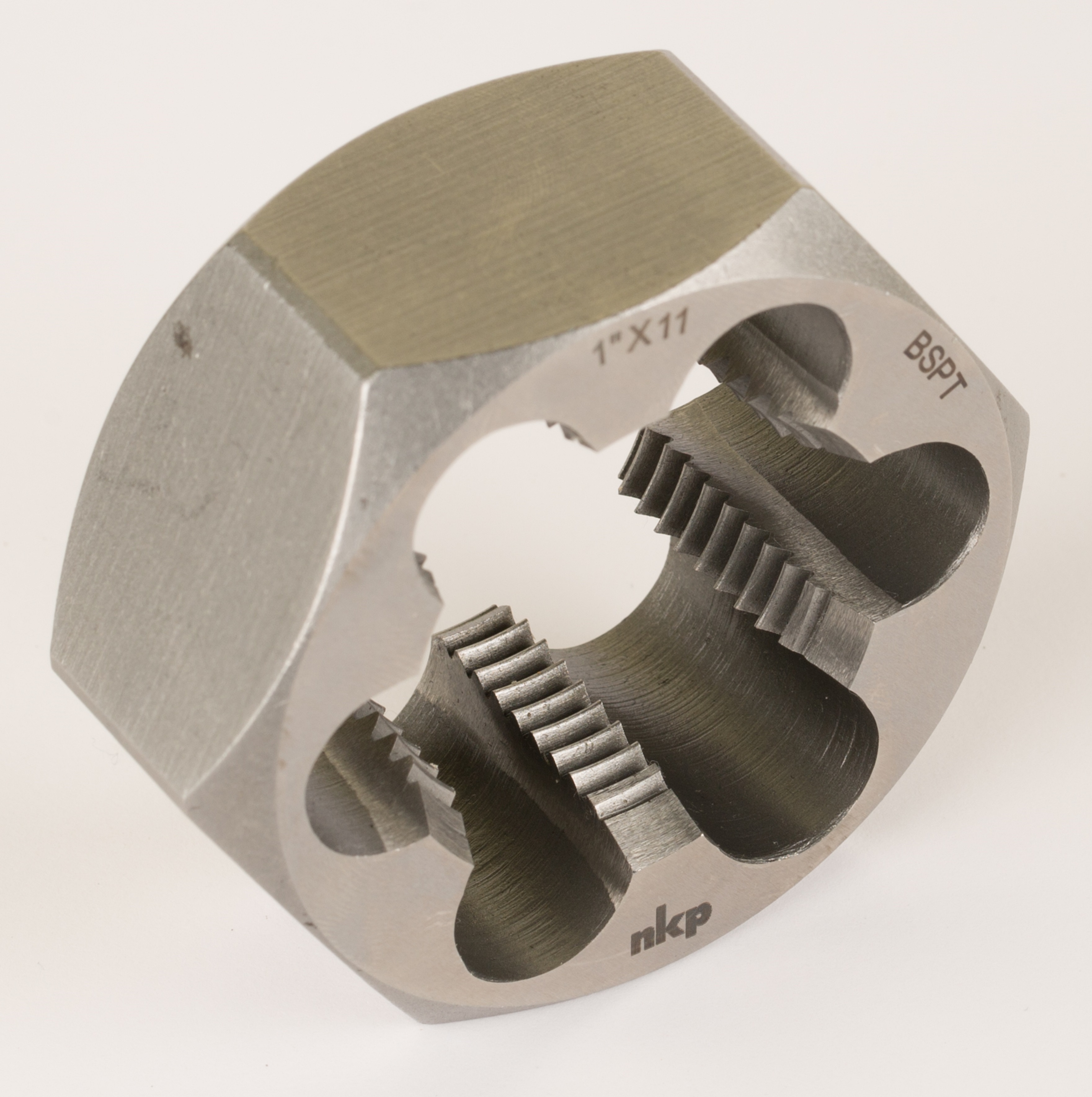

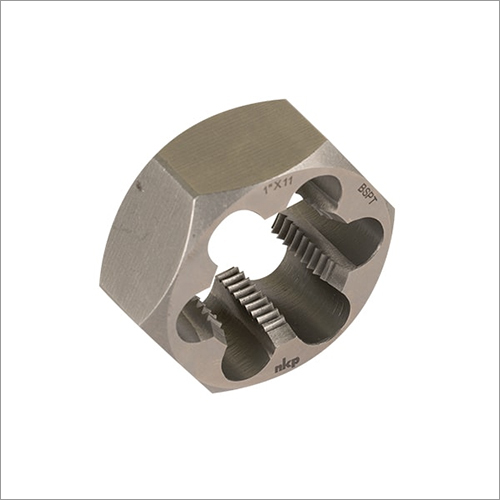

Rethreading Hexagonal Die Nut

Price 100-5000 INR/ Piece

MOQ : 1 Piece

Rethreading Hexagonal Die Nut Specification

- Die Head

- Hexagonal

- Working Process

- Thread Reconditioning / Recutting

- Life Span

- Long Lasting

- Shaping Mode

- Machining

- Material

- High-Speed Steel (HSS), Carbon Steel, Alloy Steel

- Application

- Re-threading and repairing damaged threads on bolts, rods, and pipes

- Hardness

- HRC 58-62

- Tolerance

- 0.02 mm

- Packaging Type

- Boxed or Blister Pack

- Color

- Silver, Black

- Heat Treatment

- Tempered for durability

- Thread Standards

- Metric (M), UNC, UNF, BSW, BSP, BSF, NPT

- Outer Diameter

- Varies with size

- Usage

- Manual or with die stock

- Thread Pitch

- Varies as per standard

- Available Sizes

- M3 to M52, Custom sizes available

- Cutting Edge Type

- Precision Ground

- Surface Finish

- Black Oxide, Plain

- Corrosion Resistance

- Yes

Rethreading Hexagonal Die Nut Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1-2 Days

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Domestic Market

- All India

About Rethreading Hexagonal Die Nut

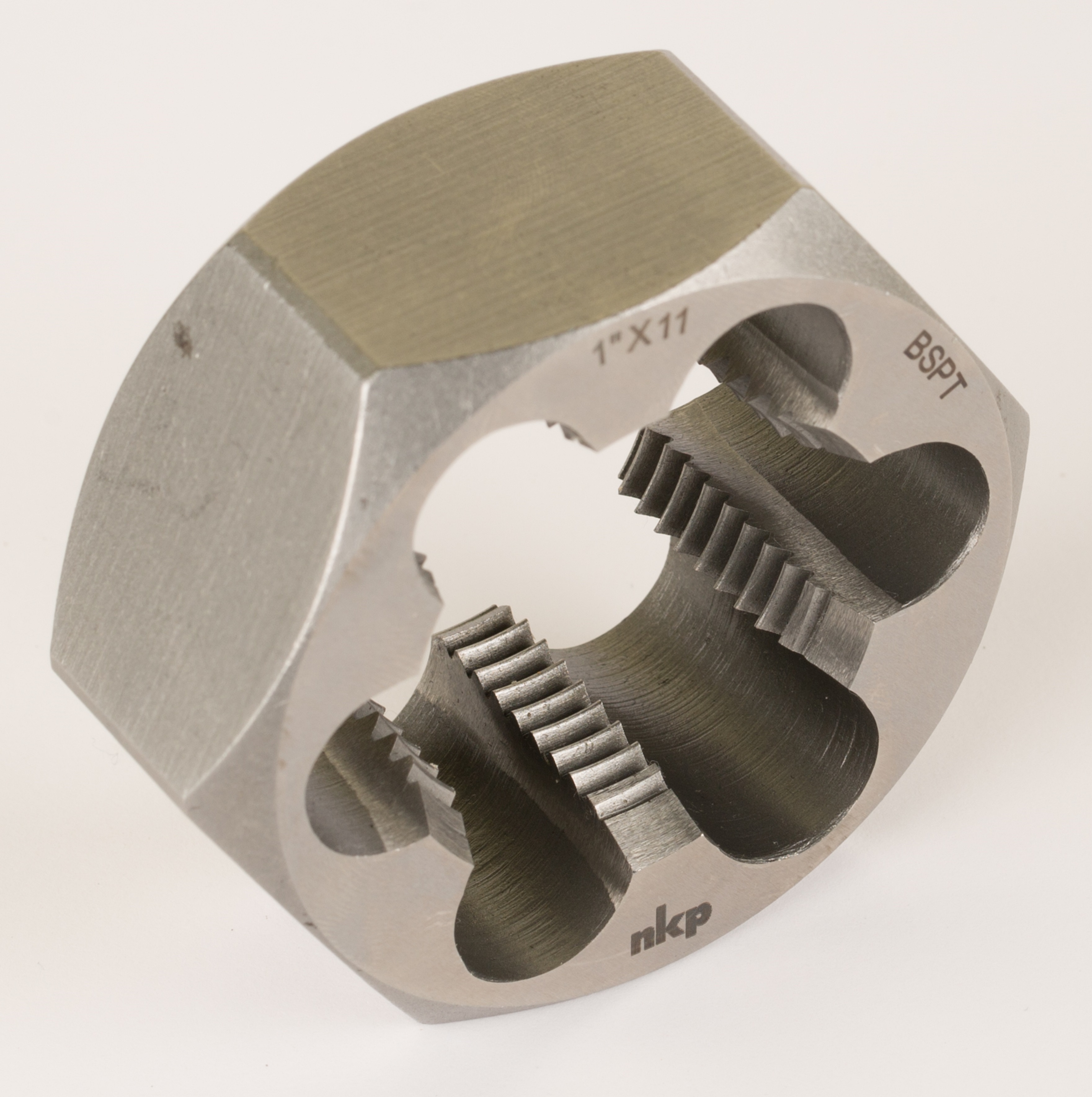

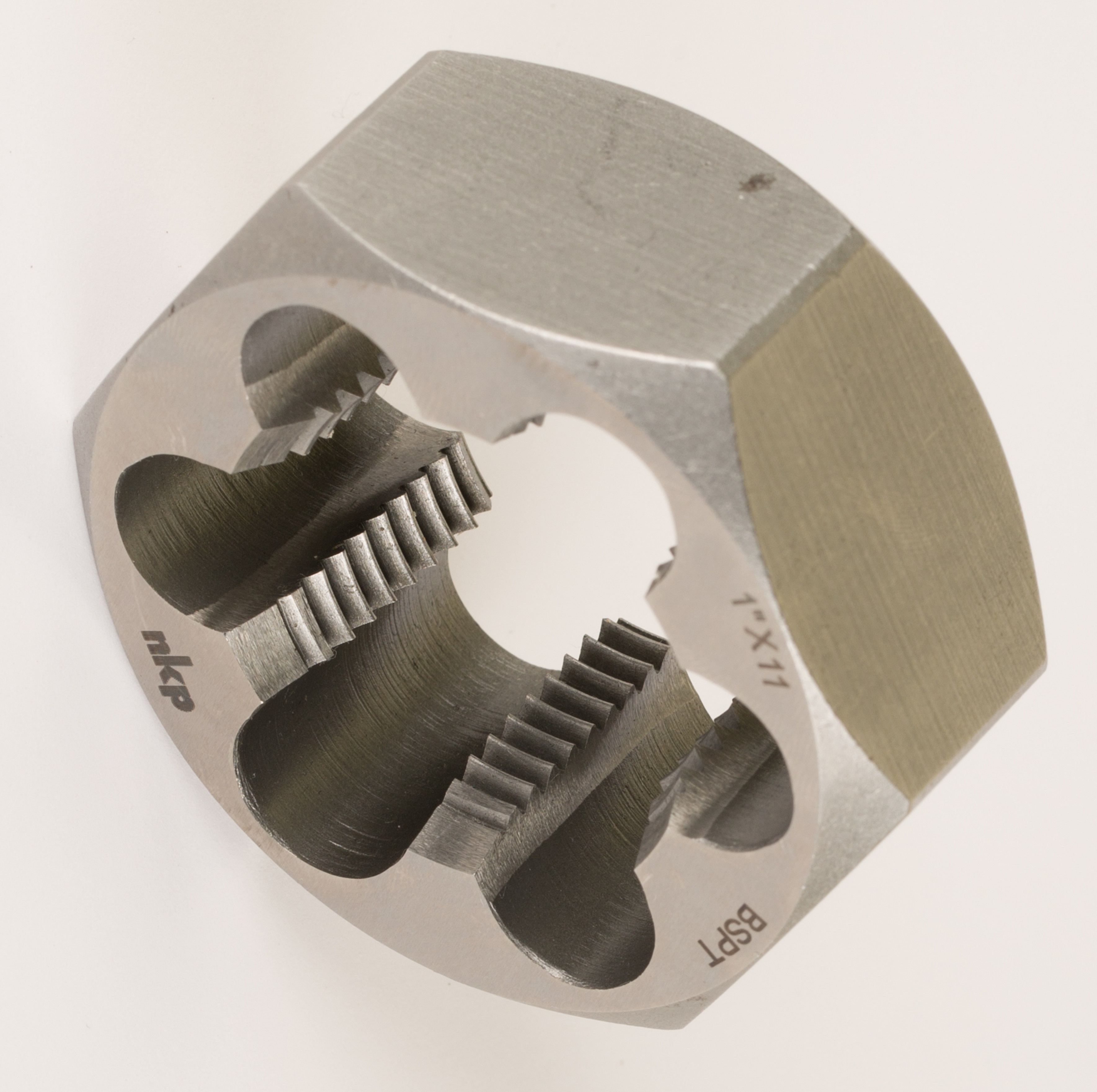

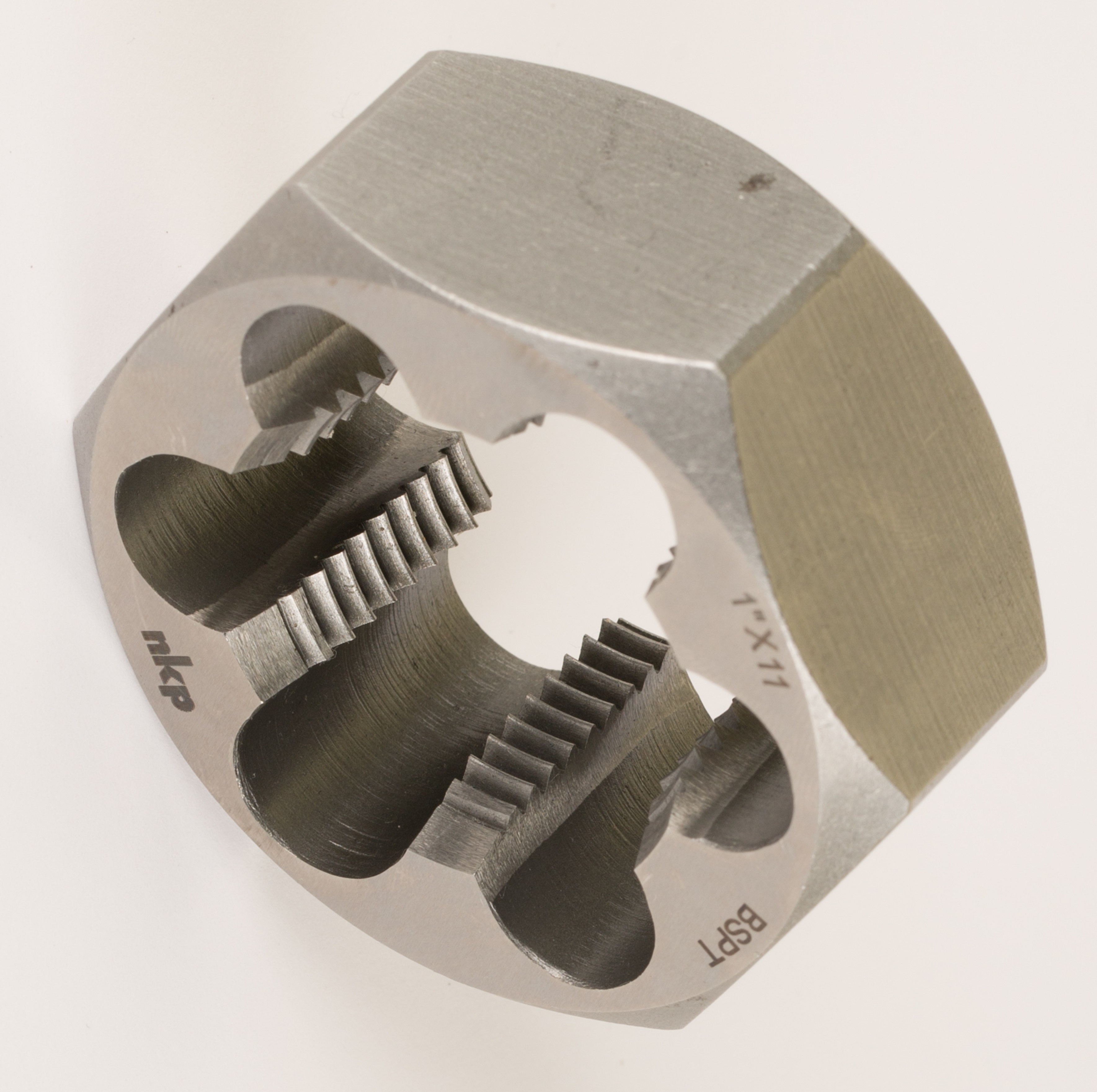

Rethreading Hexagonal Die NutThe Company specialized in manufacturing of nkp brand Thread Cutting Dies & Hex Rethreading Die Nuts for last 40 years.

It has widest range. It caters to INDIA as well as foreign buyers.

It produces standard as well as nonstandard dies , Die nuts in HSS as well as Carbon Alloy Steel in R.H., L.H., different tolerances etc.

NOTE : Rethreading Hexagonal Die Nut available in HSS as well as Carbon Steel.

Material: Available in HSS as well as in CARBON STEEL

Versatile Thread Standards and Sizes

Catering to global threading specifications, these hexagonal die nuts are compatible with major standards like Metric, UNC, UNF, BSW, BSP, BSF, and NPT. With sizes ranging from M3 to M52, and custom options available, users can confidently rethread or repair fasteners in both standard and specialized applications.

Precision Engineering for Durability

Manufactured from high-speed steel, carbon steel, or alloy steel and undergoing tempering for a hardness of HRC 58-62, the die nuts ensure a precise fit within a tolerance of 0.02 mm. The precision-ground cutting edges and choice of black oxide or plain finish provide extended tool life and improved resistance to corrosion.

User-Friendly Application and Packaging

Designed for manual operation or use with a die stock, these hexagonal die nuts are easy to handle and effective for thread restoration. Delivered in boxed or blister packaging, they are protected during transit and storage, making them suitable for exporters, manufacturers, suppliers, and wholesalers.

FAQ's of Rethreading Hexagonal Die Nut:

Q: How do I use a hexagonal die nut to repair damaged threads?

A: To use a hexagonal die nut, secure the damaged bolt, rod, or pipe in a vise, align the die nut with the existing thread, and turn it manually or with a die stock. Apply steady pressure and cutting oil to ensure clean thread reconditioning.Q: What thread standards and sizes are available for these die nuts?

A: These die nuts are produced to suit Metric (M), UNC, UNF, BSW, BSP, BSF, and NPT thread standards. Standard sizes range from M3 to M52, with custom options available to meet specific requirements.Q: When should I choose a black oxide or plain surface finish?

A: Black oxide finish is recommended for enhanced corrosion resistance and minimal glare, making it suitable for demanding environments. Plain finish is suitable for standard or less corrosive conditions where aesthetics and basic protection suffice.Q: Where are these die nuts typically used?

A: These rethreading die nuts are common in automotive repair, construction, maintenance, and manufacturing industries for repairing and restoring damaged threads on fasteners, pipes, and rods.Q: What are the primary benefits of using precision-ground cutting edges?

A: Precision-ground cutting edges provide smoother thread cutting, longer tool life, and improved accuracy, reducing the risk of cross-threading and enhancing rethreading efficiency.Q: Can I use these die nuts manually or with power tools?

A: These die nuts are primarily designed for manual use or with a compatible die stock. Using power tools is not recommended, as it may reduce precision and risk tool or workpiece damage.Q: What material options are available for these die nuts and how does that impact performance?

A: Die nuts are available in high-speed steel (HSS), carbon steel, or alloy steel. HSS offers superior durability and heat resistance, carbon steel provides dependable strength for general use, and alloy steel balances hardness and toughness for demanding applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Re Threading Hex Die Nuts Category

Hexagonal Rethreading Die Nut

Price 100-5000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : External Thread Restoration and Cutting

Life Span : Long Service Life

Material : Other, High Speed Steel (HSS) / Carbon Steel

Shaping Mode : Other, Machined

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS