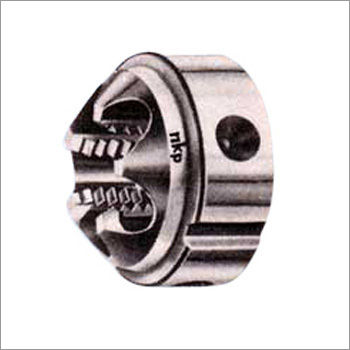

Acorn Circular Threading Dies

Price 100-5000 INR/ Piece

Acorn Circular Threading Dies Specification

- Features

- Replaceable; Precision Ground; Durable

- Cutting Capacity

- Up to M25 (varies by die size)

- Coating Type

- Uncoated / Black Oxide (varies)

- Cutting Speed

- Standard suitable for manual and machine use

- Coating

- Optional Black Oxide

- Length

- Approx. 8 mm 22 mm (depends on size)

- Material

- High Speed Steel (HSS)

- Cutting Force

- High

- Cutter Type

- External Thread Cutter

- Drill Bits Types

- Threading Dies

- Cutting Accuracy

- High Precision

- Operate Method

- Manual or Mechanical

- Shape

- Circular (Acorn Shape)

- Tool Type

- Threading Tool

- Hardness

- HRC 5862

- Operation Type

- Hand or Machine Operated

- Machine Type

- Suitable for Threading Machines & Die Stocks

- Diameter

- Range from 10 mm to 50 mm (varies)

- Maximum Torque

- Varies with Die Size

- Processing Type

- Thread Cutting

Acorn Circular Threading Dies Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1-2 Days

About Acorn Circular Threading Dies

We are dealing in the manufacturing of premium quality Acorn Circular Threading Dies which is used in fastener making industries to make highly finished threads over the metallic shank with high precision and uniformity. This compact and rigid socket like component can be easily mounted on the high speed rotating shaft of the machines with the help of special attachments. Acorn Circular Threading Dies is also provided with a silver colored coating to prevent surface damages due to rusting and corrosion.

Product details

| Country of Origin | Made in India |

| Surface Finishing | Polished |

| Shape | All |

| Material | SS |

| Color | Silver |

| Brand | nkp |

High Versatility and Precision Cut

These Acorn Circular Threading Dies excel in producing accurate external threads on rods, bars, and pipes. With options for both fine and coarse pitches, they accommodate metric and imperial systems, suiting diverse industry requirements. Their ground and polished surfaces ensure a precise cut every time, while the option for black oxide coating enhances protection in demanding environments.

Durable High-Speed Steel Construction

Crafted from high-speed steel (HSS) and hardened to HRC 58-62, these dies offer impressive durability and a long working life. The precision grinding process maximizes wear resistance, allowing repeated use and easy re-sharpening. Their robust design supports both manual and machine threading operations, ensuring consistent results even under high cutting force.

Flexible Application and Packaging

Suitable for threading a variety of metals-including stainless steel, brass, and aluminum-these dies cater to both workshop and industrial applications. They are conveniently available in individual boxes or sets, providing flexibility for different project requirements. Their circular acorn shape fits standard die stocks and threading machines for straightforward integration.

FAQ's of Acorn Circular Threading Dies:

Q: How do I select the correct Acorn Circular Threading Die for my project?

A: Choose a threading die based on the required thread size (metric or imperial), thread pitch (fine or coarse), and material to be threaded. Ensure the die size matches your rod or bar diameter and check that your threading tool accommodates the selected die.Q: What materials can be threaded using these dies?

A: These dies are engineered for threading steel, stainless steel, brass, and aluminum. Their high-speed steel (HSS) construction and high hardness let them cut effectively through various metals, providing reliable results across different materials.Q: When should I use fine pitch versus coarse pitch threading dies?

A: Fine pitch dies are ideal for applications requiring stronger tension and better thread engagement, often used in precision parts. Coarse pitch dies are preferred for rapid assembly and general-purpose connections, especially where fast threading is needed.Q: Where are Acorn Circular Threading Dies commonly used?

A: These dies are widely used in manufacturing, maintenance, repair shops, and fabrication workshops. Their versatility makes them suitable for professional tasks requiring accurate and durable threading across construction, automotive, and industrial sectors.Q: What is the process for re-sharpening or reusing these dies?

A: After cleaning the die, re-sharpening can be performed using a suitable sharpening tool or by a professional, ensuring the cutting edges are restored. Proper maintenance extends die life and supports repeated high-precision use.Q: Can these dies be operated both manually and on machines?

A: Yes, Acorn Circular Threading Dies are engineered for use with die stocks for manual threading and are also compatible with threading machines. This flexibility allows you to choose the most efficient operation method for your workflow.Q: What benefits do users get from the optional black oxide coating?

A: The optional black oxide coating enhances corrosion resistance and reduces friction during the threading process. This protection is beneficial when threading tougher materials or operating in challenging environments, extending the die's working life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Circular Thread Cutting Category

Circular Thread Cutting Dies

Price 100-5000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Material : Others, High Speed Steel (HSS) / Alloy Steel

Diameter : Range 10 mm 65 mm

Length : Standard as per die type

Coating : Optional

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS